Livelihood Challenges posed by Post-harvest Losses

Mmasichukwu rises before dawn, pacing softly about her home to prepare food for her family. Once her husband leaves for work, she travels to a nearby farm with her trusty wheelbarrow, gathering freshly plucked Ugu leaves for the market. Her family does not own the farm; they have pooled their money to purchase Ugu leaves cultivated by a local farmer on a small patch of his land. Mmasichukwu picks the leaves just before market day. It is the only way she can provide fresh produce to her customers. After travelling 15 kilometres to the farm and back, she wraps her 8-month-old baby to her back and heads to the market. She patiently waits for customers there, refreshing the leaves every few hours to stave off spoilage. Whatever remains unsold is portioned for her family’s use, while the rest is reluctantly discarded. The next market day, Mmasichukwu embarks on this arduous journey once more, trapped in a relentless cycle of toil and loss.

Doris sits amid her shipment of onions from Jos, Plateau State in Northern Nigeria. These onions, harvested and transported in sacks, endure a long journey of hundreds of kilometres before reaching her. A third of the onions have already succumbed to damage by the time they arrive. Doris meticulously sorts the remaining onions by quality, selling the lower-quality, small ones for a reduced price of NGN 500 (USD 0.63) instead of NGN 1000 (USD 1.3) per kg. At the end of the day, Doris brings the unsold onions home, storing them indoors to keep them cool. While this method is better for preserving their quality than leaving them exposed to the sun, there is still a noticeable decline in quality. As a result, Doris is compelled to lower the prices for the crops by the next market day. This constant battle against quality loss chips away at her profits, leaving Doris struggling to break even.

Bose’s daily routine has been upended. In the past, she would have joined her mother to sell tomatoes and peppers together. Since her mother’s passing, she finds it increasingly challenging to support her family solely through vegetable sales due to the unstable income from the job. Now, Bose earns income from various odd jobs, such as cleaning shops and assisting others in selling their crops, while remaining on the lookout for a more stable source of income.

While studies indicate that farmers face a 15 percent reduction in their incomes due to post-harvest loss, a more alarming scenario emerges from one of the few targeted studies conducted in Nigeria. In Osun state, tomato growers saw a drastic reduction in the percentage of gross profit margin attributed to losses, dropping from 82 percent to 17 percent in 2014

Mmasichukwu, Doris, Bose, and other farmers and traders find solutions to their post-harvest problems at ColdHubs – Nigeria’s largest provider of cold rooms as a service, where they discover solutions to their challenges.

The Origins

ColdHubs was founded by Nnaemeka Ikegwuonu, a former radio show host committed to promoting farming best practices and market price transparency. Despite improvements in on-farm processes and increased yield, crops were spoiling rapidly after harvesting due to the absence of adequate storage options. Recognising the lack of access to cooling facilities among small-scale farmers, Ikegwuonu set out to tackle the problem.

In 2015, ColdHubs introduced a walk-in cold room with a window unit air conditioner, touring it across 11 states to raise awareness among farmers about this innovative technology. While farmers welcomed the innovation, concerns arose about their ability to maintain the cold rooms over time. Hence, the concept of Cooling-as-a-Service (CaaS) was born. ColdHubs offered to own, maintain, and upgrade the cold rooms for farmers in exchange for a storage fee of NGN 200 (USD 0.25) per crate (20 kgs) per day. This approach empowered farmers with access to temperature-controlled storage solutions without the burden of investing in the equipment and taking care of its maintenance, revolutionising the agricultural landscape in Nigeria.

A decade later, ColdHubs operates 58 solar-powered cold rooms of 3 and 10 metric tonnes across 28 states of Nigeria. As recently as 2023, ColdHubs has expanded its infrastructure, introducing one 10-metric-tonne cold room and two 100-metric-tonne cold rooms. In these new rooms, ColdHubs is shifting to new technology, called Design 2.0. ColdHubs 2.0 marks a departure from the previous monoblock refrigeration system, which consolidated all cooling components into a single unit and relied on battery storage for energy.

Instead, Design 2.0 embraces split unit refrigeration, comprising six distinct components:

- Condensing unit

- Evaporator unit,

- Blower

- Ice tank with ice packs

- Air duct with damper

- Control switch

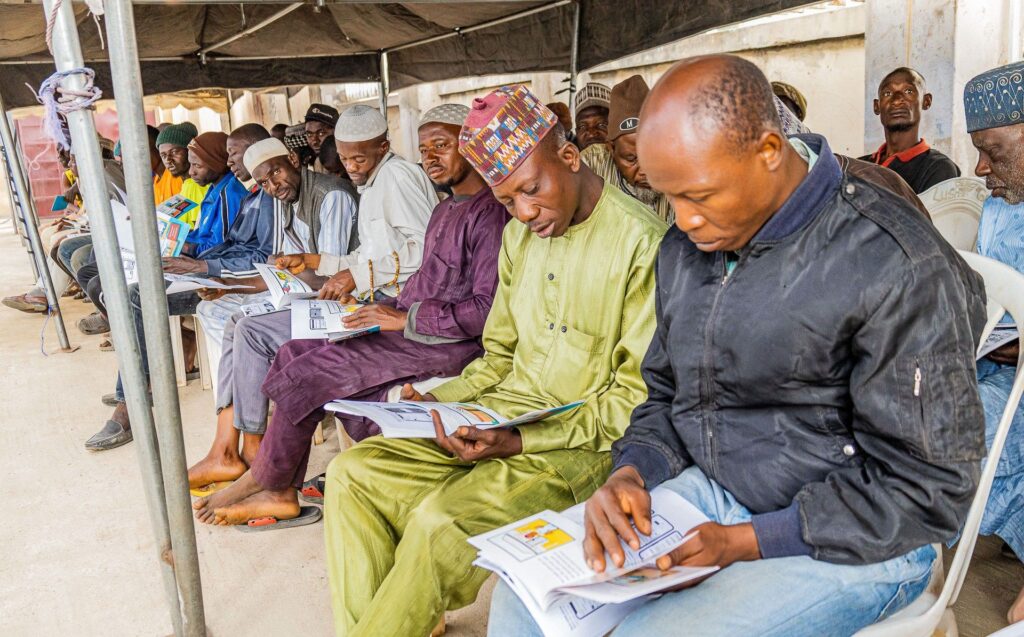

This new design stores energy in ice, offering a more sustainable approach to cooling. Additionally, seven ice points have been attached to the cold rooms, which operate on the additional solar energy generated by photovoltaics. These facilities have benefited farmers and traders like Mmasichukwu and Doris, along with 9,775 other customers, including distributors and other actors in the food supply chain. The customers stored over 3 million kilograms of produce in 2023 alone. In addition to providing CaaS, ColdHubs conducts educational campaigns to educate farmers on various topics such as seed quality, plant diseases, and post-harvest crop management. These efforts aim to ensure that high-quality crops reach the market, and farmers earn an income commensurate with work and resources invested.

Community First

In ColdHubs’ modus operandi, community engagement isn’t just a ‘nice-to-have’; it’s a guiding principle. ColdHubs trains members of the local community to serve as cold room operators, entrusted with the crucial tasks of checking crates in and out, maintaining room sanitation, and educating farmers on the importance of post-harvest cooling. All cold rooms are managed by women, a deliberate move to challenge traditional gender roles in agriculture: despite their active involvement in fieldwork, women are frequently excluded from the process of commercialising crops and receiving their rightful share of the profits.

ColdHubs partners with local female market leaders, known as Iya Oja in Nigeria’s Yoruba region, to find candidates like Bose who may be facing socio-economic challenges or violence. The cold rooms are strategically placed in safe, public locations like markets for physical accessibility. Having female operators enhances their cultural accessibility, especially for female farmers who otherwise face restrictions due to cultural norms around mobility.

ColdHubs’ proactive Sales and Marketing team engages with women at local markets to understand their lives and challenges. Separate sessions for women and men help uncover unique hurdles in crop selling, with the team reporting that women feel more at ease discussing vulnerabilities in female-only settings. In later stages, the team holds joint gender programmes to promote knowledge sharing and underscore women’s significance in agriculture and economic development. The team comprises regional representatives who are conscientious about addressing culture and power issues in the communities they serve. They intentionally link the capacity-building process to a broader agenda of social transformation in farming communities. ColdHubs trained 3,400 farmers on post-harvest management of fruits and vegetables and created 100+ jobs for women in 2023.

Between 2022 and 2023, farmers and traders using ColdHubs experienced a notable increase in average monthly income, rising from USD 60 to USD 120. This increase was made possible by the ability to store crops for delayed sales, particularly when market prices increased. Reducing food waste and adopting solar power to run the rooms, replacing diesel generators, played a significant role in avoiding nearly 3,932,560 kilograms of CO2 emissions across all hubs and ice points.

Digital Revolution

In 2021, the Your Virtual Cold Chain Assistant team visited ColdHubs’ facilities as part of a market assessment aimed at understanding how a digital tool could enhance cold room management and serve as a complementary plug-and-play solution for operating cold rooms under a servitisation business model. Since then, Coldtivate has been piloted across 14 of ColdHubs’ rooms, with 240 unique users (smallholder farmers and small-scale traders who have used the app for more than one check-in and check-out cycle).

“We are thrilled to announce that as our operations grow in scale and reach new locations, we are focusing on digitalising them. The Your Virtual Cold Chain Assistant project has provided us with Coldtivate, an all-in-one tool that fulfils our inventory management requirements and keeps our customers updated on their crates. We are integrating Coldtivate as a vital training component for hub operators before onboarding.”

Nnaemeka Chidiebere Ikegwuonu

Years of check-in and check-out data were stored in registration manuals, which operators found easier compared to digital tools like MS Excel. Behind the simplicity of manual record-keeping lay a challenge: valuable data sat untapped in forgotten corners, collecting dust. Operators faced the arduous task of manually inspecting crates every few days to identify spoiling fruits, cross-referencing registrations to determine crate ownership, and notifying farmers for collection. Many operators expressed that due to either their lack of formal education or the time constraints resulting from balancing economic and domestic responsibilities, they found the task of calculating fees and creating receipts to be daunting and susceptible to errors. Based on this feedback, Your VCCA conceptualised an all-in-one app – Coldtivate.

When new farmers join a cold room, they can be registered in the company’s records through Coldtivate. Subsequently, the cold room operator can check-in crates against the farmer’s name, recording information on the harvest date and the intended number of storage days to calculate the predicted occupancy of the room in the coming weeks. Using temperature sensors and the harvest date as a proxy for initial quality, Coldtivate calculates the remaining storage life of crates. The calculation of remaining storage life relies on ‘digital fruit twins’ developed by Empa. These twins are virtual replicas that mimic the ageing process of real fruits, using temperature and humidity data collected from sensors in the room. While the wealth of information hidden in the sensor data has largely been untapped. These digital twins have unlocked this potential of upcycling the data extracted from the cold rooms.

If the farmer owns a smartphone, they can track the remaining storage days from their phone. Those with feature phones receive an SMS two days before the recommended pick-up date, while those without any phones are contacted in person by the cold room operators. During check-out, the app automatically calculates the amount owed based on the per-crate-per-day value set by the company on the app, produces a receipt, and records whether the payment was made in cash or cashless methods.

During the pilots, ColdHubs expressed the need to monitor the movement and finances across its rooms. In response, Your VCCA created dedicated screens in Coldtivate to display utilisation and financial statistics for companies, allowing them to view aggregate values and compare performance metrics across their cooling units. This data can be downloaded in CSV format for further use and analysis. Now, the app automatically computes information on all check-ins and check-outs, revenue generated by each cold room under ColdHubs, and impact figures on food loss avoided, income increase among users, and CO2 emissions avoided for the companies.

Every Monday, farmers with smartphones receive a notification to fill out a post-usage survey, answering questions about how much they were able to sell their crops for and how much was lost despite using the cold room. Cold room operators receive similar notifications to survey their customers. This information serves two purposes. Firstly, it helps calculate the increase in income and reduction in post-harvest loss, compared against a baseline survey conducted for each farmer when they join the app. Secondly, in the future, it can be used to validate the market price prediction model integrated into the app. The app uses open-source data to predict the prices of certain commodities during the coming months, alongside a historical analysis of prices in past years. Farmers can utilise this data to determine optimal selling times for their crops. The actual selling rates collected from the post-usage survey enhance the accuracy of the prediction model.

Despite handling complex tasks, Coldtivate is designed to be highly user-friendly. All app screens feature simple icons and colours with universal meanings. For example, storage life predictions use red to indicate ‘withdraw immediately,’ while yellow and green denote ‘get ready to withdraw’ and ‘there is plenty of time to withdraw the crates,’ respectively. Farmers can also use in-app notifications to receive reminders for withdrawing their crates, especially useful when storing multiple crates. The app is free to use and easy to navigate, featuring instructions in local languages, including Igbo, Yoruba, and soon, Hausa.

During the onboarding process, each cold room operator undergoes thorough training on how to effectively utilise the Coldtivate app. Regular sessions, led by ColdHubs sales and marketing team, are dedicated to addressing inquiries and introducing new features. By fostering familiarity and imparting digital skills to operators, especially young graduates, the collaborative efforts of Your VCCA and ColdHubs have paved the way for numerous employment opportunities in the future.

Operator feedback is consistently collected to refine the app experience. This user-centred design approach results in changes such as making surveys in the app more flexible to include indicators that reflect local ways of measuring produce lost or sold, such as using ‘baskets’ or ‘sacks’ instead of just kilograms.

What does the future hold?

Cold room utilisation, while beneficial for farmers, often remains low when the sale of produce is uncertain. Waiting for better market prices, although ideal, is not always realistic. Many farmers opt to sell their crops immediately to meet their immediate financial needs.

In light of this situation, ColdHubs has collaborated with Heifer International to establish one 10 metric-tonne and two 100 metric-tonne cold rooms. These facilities allow retailers, aggregators or other food supply chain actors like Shoprite and Spar to purchase goods from the decentralised cold rooms and store them for longer periods, addressing the demand for market linkage among farmers who may struggle to access markets directly. In the future, these larger cold rooms could also assist small traders in procuring fresh fruits and vegetables, delivered to them via one of ColdHubs’ seven refrigerated trucks. This initiative aims to tackle issues like Doris’, where crops often spoil and lose economic and nutritional value by the time they reach her.

As the cold rooms continue to expand, the demand for Coldtivate grows, too. Imagine having to check for spoilage across the 5000 crates stored in the 100 MT room – an arduous and nearly impossible task. Coldtivate aids operators by informing them which crates must be checked out. To ensure the quality of the crates, the app tracks the shelf-life of the crops as they move from one cold room to another and even during transportation in the trucks until they reach the traders or the final market.

Moving forward, Coldtivate aims to enhance its capabilities further by enabling operators to map the cold room and pinpoint the exact location of the crate to be checked out. Further, it aims to streamline the check-in and check-out process through crates code scanning for increased efficiency.